Technical

Much time, effort and money has been invested in developing the unique range of Moorespeed products: all the tuning and chassis items except where noted have been designed and developed in-house.

Most of the World’s leading motorsport engineering is to be found within a 50 mile radius of Northampton (home of Moorespeed) so there is no shortage of specialist skills available whenever a task has to be out-sourced. And nothing, absolutely NOTHING has come from China.

With very few exceptions, everything shown on this website is proudly Made in Britain.

Power claims

There’s a good deal of misinformation and hype bandied around concerning power outputs: some concerns make simply unbelievable claims for their products, so beware – and check their ‘facts’.

When referring to the power outputs of our engines, we mean the brake horse power (bhp) measured at the rear wheel. In contrast, manufacturers usually quote figures measured at the crankshaft which ignore driveline losses – typically 18% with a shaft-drive BMW.

All our engine testing is conducted at TTS (Towcester Tuning Services) of Silverstone: a company with a first-class reputation and which is local to our business. And by always testing at the same facility, the results are directly comparable. Of course, varying weather conditions can make small differences to the measured output and some dynos will give slightly different results, even if all other factors are equal.

‘Fast’ dynos

We – and our customers – have also tested engines at various other locations and received peak figures within 1 or 2 bhp of the TTS dyno:

However, we also have tested our 71bhp motor at a dyno facility in Newark, and there the figure recorded was 79bhp. If you always test at this facility, then no problem, the gains/losses are relative. But if you want to compare peak horsepower with other motors, then you have a problem!

Moorespeed TTS dyno results

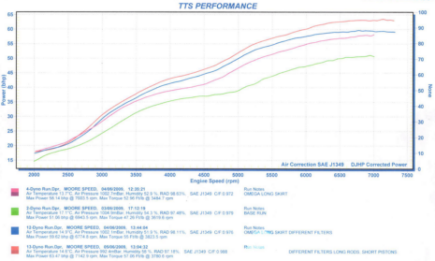

Dyno test 1994 BMW R100R road bike:

- a) Standard specification (green line)

- b) Moorespeed long skirt pistons (purple line)

- c) Moorespeed long skirt pistons and Moorespeed airfilter (blue line)

- d) Moorespeed short skirt pistons, long con-rods, Moorespeed airfilter (red line)

1994 BMW R100R: standard and with both Moorespeed long and short-skirt pistons

Click graphs to expand

Power:

Torque:

The engine of this machine had covered just 3,000 miles and was in perfect condition – and completely standard. In specification, it is exactly the same as fitted to the R100GS, with 40mm Bing carburettors. The green line indicates the power achieved: at 51.06bhp it is just what we would expect from a nicely run-in unit.

After this run, the pistons were swapped for a pair of Moorespeed long skirt pistons (no other changes) and the purple line shows the result: an extra 7.1bhp and another 5.5 ft.lb of torque at slightly lower rpm. Surely the most cost-effective (and quickest!) way to boost power by 14% at the rear wheel?

Replacing the standard airbox and filter for the free-flowing K&N air filter conversion by Moorespeed (blue line) gave a further 1.5bhp increase.

Finally, the cylinders were pulled off again and the engine re-fitted with Moorespeed short-skirt pistons on Moorespeed long con-rods (while retaining the Moorespeed airbox/filter conversion. Now the engine (red line) is producing 63.47bhp and 57.06 ft.lb of torque. That’s a 24% power hike over standard!

And remember, in this specification, the engine development is only a couple of rungs up the performance ladder. Add gas flowing and a sports cam and it will really fly!

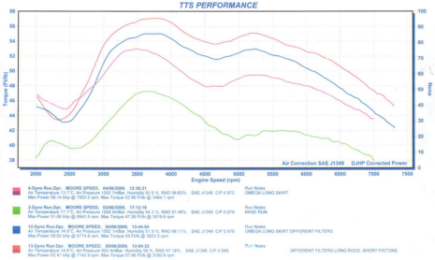

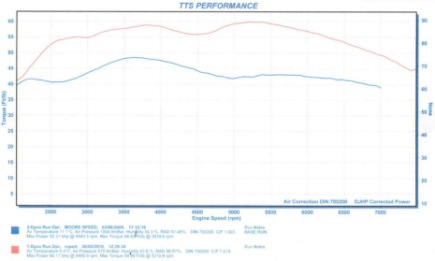

Standard R100GS v R100GS with Moorespeed long-skirt pistons, airfilter and exhaust

Click graphs to expand

Power:

Torque:

This is the engine used by Rupert Shaw in his Moorespeed Tuareg Rally racer (see ‘Projects’), where he wanted a really strong mid-range performance rather than outright power. Consequently, he opted for Moorespeed long-skirt pistons, gas-flowed head, Moorespeed K&N filter conversion (kept out the desert sand!) and Moorespeed exhaust system (40mm). He retained the 40mm Bing carburettors, though Richard modified these to flow more air.

On these charts, the red line indicates Rupert’s engine (which incidentally has some 69,000 miles on its bores) while the blue line shows the performance of a standard R100GS engine. As you can see, there’s more power and torque right from 2,000rpm – peaking some 14bhp higher than standard!

The engine’s crankshaft was also lightened and balanced – it has remarkably low vibration – and it remains a very easy to use, tractable powerplant.

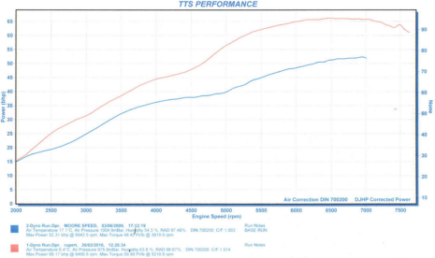

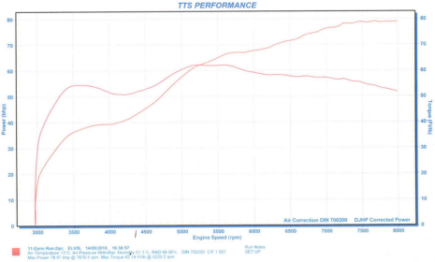

R100GS with Moorespeed long con rod/short skirt pistons, sports cam shaft, airfilter and exhaust

Click graph to expand

Power and Torque:

This Moorespeed-framed R100GS is used as everyday transport as well as a rally bike, and the rider’s main requirement was power: lots of it!

The specification therefore centred around the Moorespeed long con-rod/short skirt pistons set-up, with a gas-flowed head, sports cam (BMW 336), Moorespeed K&N filter conversion and 40mm exhaust system. In addition, he opted for Keihin CR slide carburettors plus a fully balanced and lightened crankshaft. The power curve shows not only an impressive 79bhp peak – but also how it betters the standard GS engine from a mere 4,750rpm onwards! Meanwhile, the torque curve tells its own story, bettering the standard model from 3,000rpm and delivering over 50 ft.lbs from 3,250 rpm right up to 8,000rpm – more than the standard engine achieves at its peak of 3,600Rrpm!

While this specification may seem a little extreme for everyday road use, the engine pulls very strongly from 1,500rpm – the only ‘cost’ of this engine work being a tick-over that is rather problematical. A sacrifice which its owner is happy to make...

Moorespeed/Omega pistons

The high-compression pistons were designed by Richard in collaboration with Omega Pistons who manufacture them exclusively for Moorespeed. Omega’s clients have included the 19???? Ducati Marlboro Moto GP race team, ??? and ????. World class products by any reckoning.

The initial batch of Moorespeed long-skirt pistons – like all the short-skirt pistons – were machined from solid, but subsequent batches are made from forgings. There are pros and cons to both methods of production, but machining from solid is the only viable option for small production runs, as it needed a £12,000 investment by Richard to make the tooling for the current castings. That level of commitment demonstrates Richard’s determination to ‘do the job right’.

As the 750cc race class is a very specialised market, these pistons are machined from solid, as are those for the big bore Open Class race engines.

Watch out for other road bike developments too….

Remember, these pistons are unique to Moorespeed – though Motobins are also permitted to retail them as part of their 50298 Power Piston Kit.

Why not twin-plug heads?

Different engine tuners have different ideas: it would be a dull world if they didn’t – but Richard agrees with the sentiments of noted engine designer Keith Duckworth: “If you need more than one plug per cylinder, you’ve got a problem”. Certainly BMW went to the two-plug route in 2004 with their 1200 oilhead twin, but that was for emissions reasons, and is no longer used.

The airhead twin’s cylinder head is not suited to twin-plugging: the only space available for the extra plug is between the push rod tubes – offset from the centre and spoiling the smooth combustion chamber shape. You are also creating more complexity and weight with the need for additional ignition components, while also compromising ignition timing. The only real attraction of twin-plugging is for those engine tuners who do not have a modern design piston…

Richard has twin-plugged an R100 head in the past, but only so that it could use low grade fuel – and now that situation is better served by using his programmable digital ignition system.

Why short pistons/long rods?

The short-skirt high compression pistons are lighter, have less side loading and offer less drag in the bore. The little end is mounted 15mm closer to the piston crown – which in turn means that the con-rods have to be longer to compensate for this difference. A longer (and in this case, stronger) rod gives increased dwell near the top of the compression stroke, allowing more time for complete combustion.

Which camshaft?

Camshafts can make a profound difference to an engine’s characteristics as well as its power. We offer an increasing range of cam shafts, depending on the rider’s needs – from mild to wild… But please to call to discuss what you want to achieve from your engine before making your choice: some riders enjoy the fun of a ‘peaky’ cam shaft grind, while others will prefer more ‘grunt’ at the expense of peak horsepower.

Steps to performance tuning

If you want more performance from your 1000cc road bike engine, then the very first step should be to fit a pair of Moorespeed high compression pistons: it’s the biggest single boost in performance that you can buy – and also the most cost-effective.

Of course, it would be a waste of time to fit these pistons if the valve gear is not in good condition. If the valves you are running have done more than 45,000 miles, then they should be replaced anyway: send your heads to Moorespeed to have the valves and their seats inspected. Now would be a good time to have the heads gas flowed and maybe bigger valves fitted. Moorespeed valves are actually superior in quality to OE valves, and actually cost less….

If you are now burning the fuel/air mixture more efficiently, then you can consider getting a greater volume of the mixture through the heads: so now look at the Moorespeed free-flowing air filter system, and maybe getting the carbs reworked – or even replaced with Dell’Ortos.

Want more? Then a different camshaft could be on the cards – and/or even a big bore (1001cc) kit…

Of course, if your existing engine is an 800, then it would make economic sense to go straight to the big bore kit with high compression pistons. As R80 models command lower prices than R100s, this can be quite a viable option. Call for details.